Welcome to Fight Tech Manufacturing Sdn Bhd. Contact Us Now

Mon - Fri 8:30 - 5:30, Sat 8:00 - 12:30, Sunday - CLOSED

Welcome to Fight Tech Manufacturing Sdn Bhd. Contact Us Now

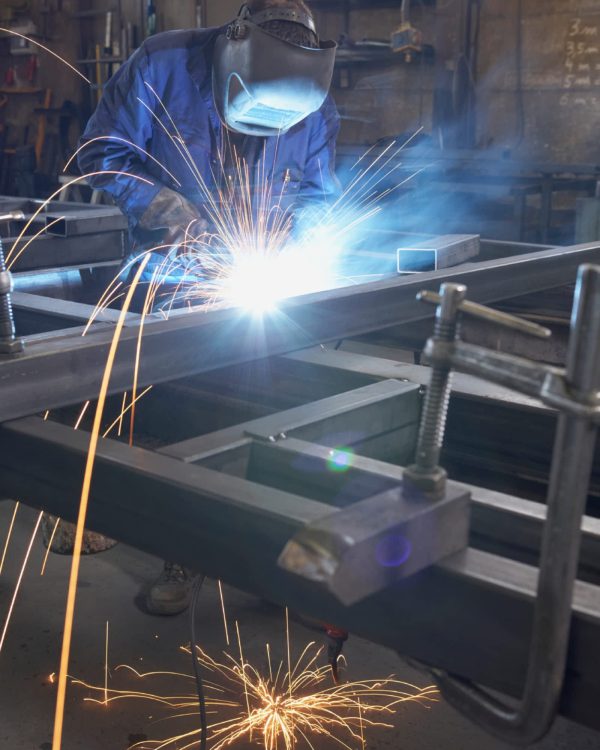

Our welding services encompass a range of techniques, including MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, arc welding, spot welding, and more. Each technique has its advantages and is suited for specific applications, depending on factors such as metal type, thickness, and desired weld strength.

Our professional welding services adhere to strict quality standards to ensure the highest level of craftsmanship. Welding technicians may perform inspections, tests, and certifications to verify the quality and integrity of the welds, meeting industry standards and regulations.

Our welders have a deep understanding of the scientific principles involved. This expertise allows us to transform welding from a manual operation into an automated production process, ensuring precision, consistency, and quality in our welding services.

The fabrication of the structure table

involves welding the shelf structure to

minimize the impact of heat, such as

preventing square tube bending and size

reduction. This ensures the stability and

durability of the table.

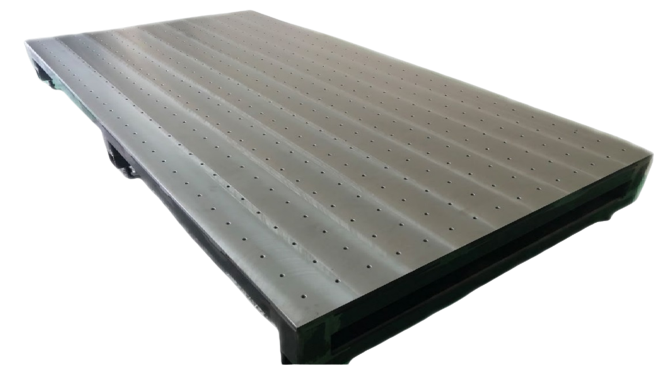

To achieve precise and accurate results, the

table is processed using a CNC Gantry

Milling Machine. This advanced machine

allows for high-precision machining with a

plane accuracy of 0.1mm. The holes for the

stopper on the table are processed in a single operation, ensuring consistency and proper alignment.

The fabrication process of the structure table combines skilled welding techniques and the use of advanced CNC machinery. This enables us to deliver a table that meets strict quality standards, offering stability, functionality, and precision.

Our HSG Laser Cutting machine are known for their high cutting speeds, enabling quick production turnaround times. It offer efficient cutting processes, reducing material waste and optimizing production efficiency.

Our HSG Laser Cutting machines can cut a wide range of materials, including metals (such as stainless steel, aluminum, and carbon steel).

When it comes to mild steel, our RAYCUS Fiber Laser can cut thicknesses of up to 15mm with accuracy and reliability.

For stainless steel, we can achieve clean and precise cuts on materials up to 8mm thick.

Additionally, when working with aluminum, our laser machine can cut through thicknesses of up to 6mm, ensuring accurate and consistent results.

Our Deratech press brakes are designed to handle a wide range of materials, including mild steel, stainless steel, aluminum, and other non-ferrous metals. They can accommodate varying thicknesses and sizes of sheet metal, making them suitable for diverse metal fabrication applications.

Deratech press brakes offer precise bending capabilities, allowing for accurate angles and dimensions. They are equipped with advanced CNC controls and back gauges, enabling precise control over the bending process and achieving consistent results.

The CNC control system allows for quick and efficient programming of bending sequences, reducing setup time and increasing productivity.

DMTG VDLS 1300 known as a computer numerical control milling machine, is a versatile and precise machining tool used for cutting, shaping, and drilling various materials with high precision.

CNC milling machines are a key asset in modern manufacturing processes, offering high precision, automation, and versatility. They enable the efficient production of complex parts with tight tolerances, contributing to improved productivity and product quality.

It also can perform a wide range of machining operations, including contouring, drilling, facing, pocketing, and slotting. They can consistently produce high-quality parts with repeatable results, minimizing errors and variations.

Multiple operations can be performed in a single setup, enhancing productivity and reducing overall production time.

DMTG CLS20 operate by rotating a workpiece on its axis while a stationary cutting tool removes material to shape the part. The cutting tool can move along multiple axes, allowing for various turning operations such as facing, turning, grooving, threading, and tapering.

CNC lathes can handle a wide range of materials, including metal, plastic, and wood.

CNC lathes offer high precision and accuracy, enabling tight tolerances and excellent surface finishes. It also ensures consistent and repeatable results, minimizing errors and variations.

The Nordson powder coating gun is renowned for its reliability, precision, and versatility. It utilizes electrostatic technology to apply a uniform and controlled layer of powder coating onto the workpieces, ensuring excellent adhesion and coverage. The gun's adjustable settings allow for precise control of powder flow, pattern size, and spray velocity, providing flexibility to meet different coating requirements.

Our powder coating oven, measuring 6 meters in length, 3 meters in width, and 3 meters in height, is equipped with the industry-leading Nordson powder coating gun.

Powder coatings provide a highly durable finish that is resistant to chipping, scratching, fading, and corrosion. The cured coating creates a protective barrier that can withstand harsh environmental conditions, making it suitable for both indoor and outdoor applications. Our team of experienced professionals ensures that each project is executed with precision and attention to detail, delivering high-quality and durable finishes that meet your specific requirements.

Fight Tech Manufacturing Sdn Bhd specialises in high precision engineering and fabrication works, serving a diversified range of industries

Copyright © 2023 FIGHT TECH MANUFACTURING SDN BHD (1431021-K). All Rights Reserved. Website Managed by Bigdomain.my